Welcome to our comprehensive guide on soundproofing batts! In this article, we will explore the various aspects of soundproofing batts, from the basics to the practical applications and everything in between. Whether you’re looking to reduce noise in your home, office, or any other space, understanding the science and benefits of soundproofing batts is key. So let’s dive in and explore the world of soundproofing batts together!

Understanding the Basics of Soundproofing Batts

Soundproofing batts, also known as insulation batts, are materials specifically designed to absorb and reduce sound waves. These batts are commonly made from materials such as fiberglass, mineral wool, or recycled denim, which have excellent sound absorption properties. By incorporating these batts into the structure of a room, you can significantly reduce the amount of sound that enters or leaves the space.

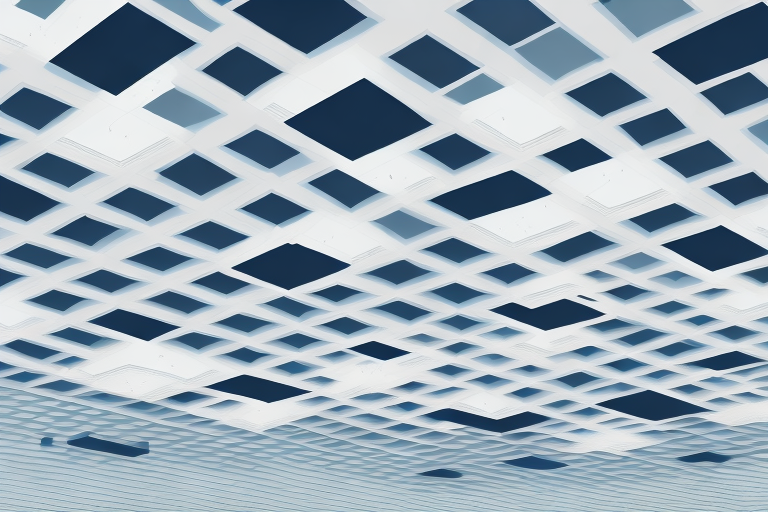

Typically, soundproofing batts are installed in walls, ceilings, or floors to create a barrier that prevents sound waves from traveling through. This is especially beneficial if you live in a noisy neighborhood or have loud appliances or equipment in your home. Soundproofing batts provide an effective solution to minimize unwanted noise and create a more peaceful and comfortable environment.

When choosing soundproofing batts, it is important to consider the thickness and density of the material. Thicker and denser batts are more effective at absorbing sound waves and reducing noise transmission. Additionally, the installation process of soundproofing batts is relatively straightforward and can be done by homeowners with basic DIY skills. However, it is recommended to consult with a professional to ensure proper installation and maximize the effectiveness of the batts.

The Science Behind Soundproofing Batts: How Do They Work?

To understand how soundproofing batts work, let’s look at the science behind it. Sound waves are essentially vibrations that travel through the air. When these waves encounter a solid object, such as a wall, some of the energy is transmitted through the object, while the rest is absorbed or reflected.

Soundproofing batts work by capturing and absorbing the sound waves that pass through the barrier. The densely packed fibers within the batts effectively trap the sound energy, converting it into heat. This absorption process reduces the amount of sound that can pass through the batts and into the adjacent spaces.

It’s important to note that soundproofing batts are not designed to completely eliminate all sound. Instead, they significantly reduce the intensity of the sound waves, providing a quieter and more peaceful environment.

Soundproofing batts are commonly made from materials such as fiberglass or mineral wool. These materials have excellent sound-absorbing properties due to their high density and ability to trap air pockets. The fibers within the batts are designed to disrupt and scatter the sound waves, preventing them from easily passing through the material.

Different Types of Soundproofing Batts: Which One is Right for You?

When it comes to choosing the right soundproofing batts for your specific needs, there are several factors to consider. The type of material, thickness, and density all play a significant role in determining the effectiveness of the batts.

One common type of soundproofing batts is made from fiberglass. Fiberglass batts are lightweight, easy to install, and provide excellent sound absorption properties. They are widely available and generally cost-effective, making them a popular choice for residential applications.

Another option is mineral wool batts. These batts are manufactured from volcanic rock or slag, making them highly fire-resistant and dense. Mineral wool batts are known for their superior sound absorption capabilities and are frequently used in commercial buildings or areas with high noise levels.

Recycled denim batts, on the other hand, are an eco-friendly alternative. Made from shredded post-consumer denim, these batts provide excellent sound absorption and are free from harmful chemicals typically found in other insulation materials.

Ultimately, the choice of soundproofing batts depends on the specific requirements of your project, budget, and personal preferences. Consulting with a soundproofing professional can help you determine the best option for your needs.

In addition to fiberglass, mineral wool, and recycled denim batts, there are other types of soundproofing batts available on the market. One such option is cellulose batts, which are made from recycled paper fibers treated with fire retardants. Cellulose batts offer good sound absorption properties and are often used in retrofitting existing structures.