In today’s modern world, noise pollution has become a prevalent issue that affects our daily lives. Whether it’s the constant hum of traffic outside your window, the loud conversations from neighboring offices, or the blaring music from a nearby party, unwanted noise can be extremely disruptive and lead to increased stress levels. Fortunately, soundproofing techniques offer a solution to combat this problem, and one effective method that has gained popularity is the use of soundproofing sponges.

Understanding the Basics of Soundproofing

Before diving into the world of soundproofing sponges, it’s crucial to understand the fundamentals of soundproofing. Sound is essentially vibrations that travel through air, and when these vibrations encounter a barrier, they can be absorbed, reflected, or transmitted. The goal of soundproofing is to minimize the transmission of sound from one area to another by reducing the vibrations that pass through various surfaces.

Traditional soundproofing methods often involve using thick, heavy materials such as concrete or drywall to create a physical barrier. While these methods can be effective to some extent, they can be costly, time-consuming, and may not always be feasible in certain spaces. This is where soundproofing sponges come into play.

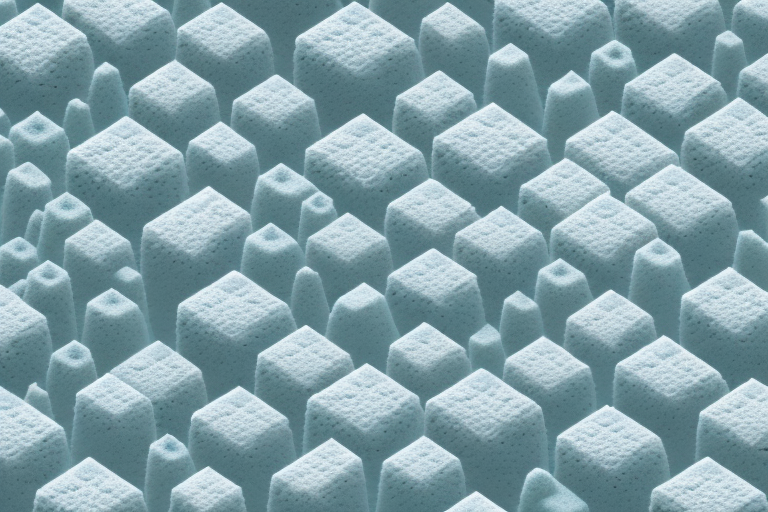

Soundproofing sponges, also known as acoustic foam panels, are a popular alternative to traditional soundproofing methods. These foam panels are designed to absorb sound waves, reducing echo and reverberation in a room. They are made from a special type of foam that is engineered to have specific acoustic properties.

Soundproofing sponges are lightweight and easy to install, making them a convenient option for soundproofing various spaces. They can be cut into different shapes and sizes to fit specific areas, such as walls, ceilings, or even inside recording studios. Additionally, they come in a variety of colors and designs, allowing for customization and aesthetic appeal.

When properly installed, soundproofing sponges can significantly improve the acoustics of a room by reducing unwanted noise and improving sound quality. They are commonly used in home theaters, recording studios, offices, and other spaces where sound control is essential.

The Role of Acoustic Materials in Noise Reduction

Acoustic materials play a vital role in reducing noise levels by absorbing sound energy. These materials are specifically designed to dampen, attenuate, or absorb sound waves, preventing them from bouncing off surfaces and spreading throughout a room. The primary purpose of using acoustic materials is to create an acoustic environment that is more conducive to concentration, relaxation, or privacy, depending on the specific needs of the space.

Soundproofing sponges, also known as acoustic foam or sound-absorbing foam, are among the most commonly utilized acoustic materials. These sponges are made from open-cell polyurethane foam, a lightweight and highly porous material that efficiently absorbs sound waves.

Another commonly used acoustic material is mass-loaded vinyl (MLV). MLV is a dense, flexible material that is effective in blocking sound transmission. It is often used in walls, floors, and ceilings to create a barrier that prevents sound from passing through. MLV is particularly useful in reducing low-frequency noise, such as traffic or machinery sounds.

In addition to sound absorption and sound blocking materials, there are also sound diffusers. Sound diffusers are designed to scatter sound waves in different directions, reducing echoes and creating a more balanced acoustic environment. These diffusers are often used in recording studios, concert halls, and auditoriums to enhance the quality of sound and improve the overall listening experience.

Exploring the Benefits of Using Sponges for Soundproofing

The use of sponges for soundproofing offers numerous benefits for both residential and commercial spaces. One of the notable advantages is the ease of installation. Unlike other soundproofing methods that require extensive construction work, soundproofing sponges are simple to install and can be easily attached to walls, ceilings, or any other surface in need of acoustic treatment.

Another significant benefit of using soundproofing sponges is their ability to absorb a wide range of sound frequencies. These sponges are designed with unique internal structures and patterns that facilitate the absorption of sound waves across the frequency spectrum. Consequently, whether you’re dealing with high-pitched noises, low-frequency vibrations, or anything in between, soundproofing sponges can effectively reduce the intensity of unwanted sounds.

In addition to their sound absorption capabilities, soundproofing sponges also improve the overall acoustics of a space. By reducing echo and reverberation, these sponges can enhance the clarity of speech, improve audio quality, and create a more enjoyable listening experience. This makes them particularly beneficial in settings such as home theaters, recording studios, conference rooms, or any space where sound quality is crucial.

Furthermore, soundproofing sponges are highly versatile and customizable. They come in various shapes, sizes, and thicknesses, allowing for tailored soundproofing solutions to meet specific needs. Whether you need to soundproof a small room or a large auditorium, there are soundproofing sponges available to suit your requirements.

Different Types of Soundproofing Sponges and their Properties

When it comes to soundproofing sponges, it’s essential to understand that not all sponges are created equal. Different types of sponges are designed to address specific soundproofing needs and offer varying levels of performance. Let’s explore some of the common types of soundproofing sponges and their unique properties:

- 1. Egg Crate Foam: This type of sponge features a characteristic egg crate pattern, which optimizes sound absorption while providing structural support. Egg crate foam is highly efficient in reducing mid to high-frequency sounds and is often used in recording studios.

- 2. Pyramids Foam: Pyramids foam is known for its visually appealing pyramid-shaped surface. This design allows for increased surface area, which further enhances sound absorption. It is commonly used in commercial spaces to control reverberation and echo.

- 3. Wedge Foam: Wedge foam is widely recognized for its excellent absorption performance across a wide range of frequencies. Its angular shape and varying thickness make it a versatile option suitable for various applications, including home theaters and vocal booths.

- 4. Bass Traps: Bass traps are specifically designed to address low-frequency sounds, which can be particularly challenging to mitigate. These specialized sponges effectively absorb bass frequencies and can significantly improve the acoustic quality of a room.

5. Acoustic Panels: Acoustic panels are another popular type of soundproofing sponge. These panels are typically made of dense foam or fiberglass and are designed to absorb sound waves, reducing echo and reverberation. They are commonly used in auditoriums, conference rooms, and music studios to improve sound quality.

6. Noise Barrier Sponges: Noise barrier sponges are specifically engineered to block and absorb sound. They are made of dense materials, such as rubber or vinyl, and are often used in construction projects to reduce noise transmission between rooms or buildings. Noise barrier sponges are effective in minimizing the impact of external noise sources, such as traffic or machinery.

How to Choose the Right Sponge for Your Soundproofing Needs

Choosing the right soundproofing sponge depends on several factors, including the specific sound issues you’re trying to address, the size and shape of the space, and your budget. Here are some key considerations to keep in mind when selecting soundproofing sponges:

- 1. Soundproofing Goals: Determine the primary objective of your soundproofing project. Are you primarily concerned about reducing noise from outside sources, or do you need to control the acoustics within a room?

- 2. Frequency Range: Identify the dominant frequencies you’re trying to attenuate. Different sponges excel at absorbing specific sound frequencies, so selecting the right one for your needs is crucial.

- 3. Room Dimensions: Consider the size, shape, and layout of the room. Larger spaces or irregularly shaped rooms may require a combination of different types of sponges to achieve optimal soundproofing outcomes.

- 4. Budget: Determine your budget for the project. While soundproofing sponges offer a cost-effective solution compared to other soundproofing methods, prices can vary depending on the type and quality of the sponge.

5. Material Composition: Take into account the material composition of the soundproofing sponge. Different materials have varying levels of sound absorption and insulation properties. Common materials used in soundproofing sponges include foam, fiberglass, and mineral wool.

6. Installation Method: Consider the ease of installation for the soundproofing sponge. Some sponges may require professional installation, while others can be easily DIY-installed with adhesive or by simply placing them in the desired location.

Step-by-Step Guide to Installing Soundproofing Sponges in Your Space

Installing soundproofing sponges doesn’t have to be a complicated process. With some basic tools and a little bit of patience, you can transform a noisy space into a peaceful oasis. Follow these steps to install soundproofing sponges effectively:

- 1. Prepare the Surface: Ensure that the surface you’ll be attaching the sponges to is clean, dry, and free from any dust or debris. This will help improve the adhesion and longevity of the sponges.

- 2. Measure and Mark: Measure the dimensions of the area you plan to cover with the soundproofing sponges. Use a pencil or marker to make light marks on the surface, indicating where the sponges will be placed.

- 3. Cut the Sponges: Using a utility knife or a serrated edge, carefully cut the soundproofing sponges according to the desired dimensions. Take your time to ensure accurate cuts.

- 4. Apply Adhesive: Apply an appropriate adhesive to the back of the sponge. It’s essential to use adhesive recommended by the manufacturer or consult with a professional to ensure proper adhesion and avoid any damage to the surface.

- 5. Attach the Sponges: Carefully place the soundproofing sponges onto the marked areas, pressing firmly to ensure good contact with the surface. Make sure the sponges are aligned correctly and are securely attached.

- 6. Review and Adjust: Once all the sponges are in place, step back and review the overall installation. Make any necessary adjustments to ensure uniform coverage and address any gaps or overlaps.

7. Allow the Adhesive to Cure: After attaching the soundproofing sponges, it’s important to allow the adhesive to cure fully. Follow the manufacturer’s instructions for the recommended curing time. This will ensure that the sponges are securely bonded to the surface and will provide optimal soundproofing performance.

8. Maintain and Clean the Sponges: Regular maintenance and cleaning of the soundproofing sponges will help prolong their effectiveness. Use a soft brush or vacuum cleaner attachment to remove any dust or debris that may accumulate on the surface of the sponges. Avoid using harsh chemicals or abrasive materials that could damage the sponges.